Discover the latest news, trends and happenings at Well Data Labs

The Digital Oilfield – Then and Now

Much has been written about the digital oilfield, just Google it and you’ll get pages of results. The term has been around for nearly 20 years, and we thought it would be fun to provide a high-level overview of what it means and assess where we are in terms of progress. There is a list of several resources at the end of the post if you’re interested in reading more. Or just Google it!

Ok, let’s start with defining “digital oilfield.” Essentially it is a concept within the oil and gas industry that intersects technology, data, automation, and people. In its simplest form, the digital oilfield allows companies to do more with less. It integrates technology, data, and processes to help companies leverage existing resources (people) more effectively, make better-informed decisions, increase operational efficiency, maximize recovery, and decrease HSE risk. The goal is straightforward – companies can visualize reserves more clearly; optimize drilling, completions and production plans; and manage operations more efficiently – but the reality and implementation are not. read more…

Predict Trouble Stages Using Rock and Frac Data

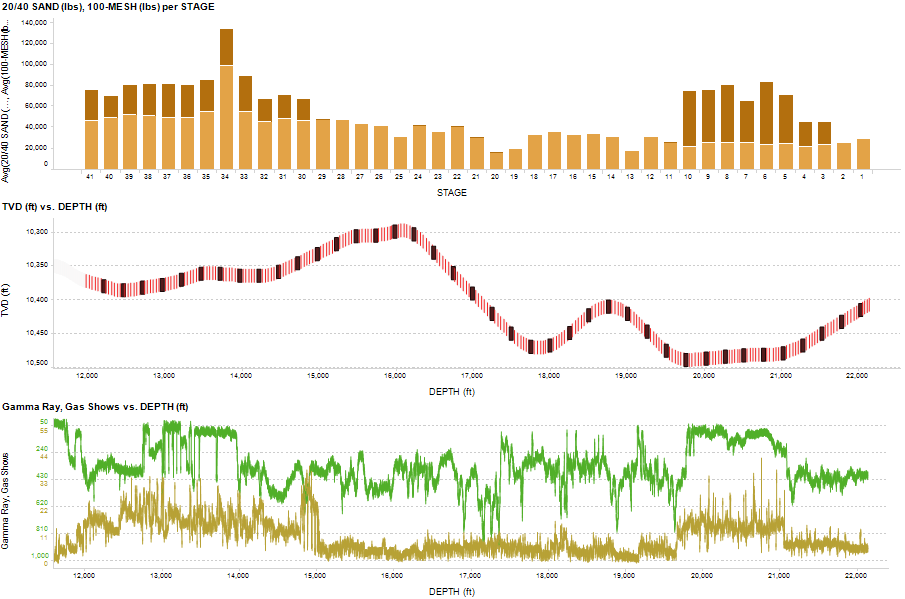

Integrating Rock Properties and Fracture Treatment Data to Help Optimize Completions Design

In case you missed this paper on the Society of Petroleum Engineers (SPE) OnePetro website, a team of experts from Hawkwood Energy, FractureID, and Well Data Labs describe how engineers can optimize their completions design by using a multivariate approach to understand unique rock types and their impact on completion responses.

In this study of six Eagle Ford wells, proprietary high-resolution geomechanical data captured at the drill bit using FractureID’s Drillbit Geomechanics™ technology and high-frequency fracture treatment data were standardized, QC’ed, normalized, and analyzed using Well Data Labs’ frac data management and analysis platform. The approach combined critical rock properties, high-frequency fracture treatment data including treating pressures, rates, and fluid and proppant volumes, and a fast-analytical methodology to analyze the geomechanical and completions database. read more…

Data Frequency: Every Second Matters

Data Resolution – Why is it important?

New software is allowing companies to capture and store more granular data than ever. In O&G, specially in completions operations, some of the most detailed data is acquired off field equipment at a one-second level. These operations generate gigantic files that usually end up sitting on an operator’s share drive and rarely used, yet they have an immense potential for answering challenging questions.

Although data is considered the oil of the digital era, more data does not automatically translate into better analysis. Anyone who has opened a post-frac one-second CSV knows this all too well. Quality data delivery has not historically been a priority in completion jobs and has resulted in a mishmash of static post-job reports and unknown-quality one second data. Analyzing a pressure signal using static reports or data with the wrong frequency can not only be misleading, but also time-consuming and tedious. In addition to the lack of consistency among vendors, hydraulic fracturing pressure data is subject to several limitations. Some of these include signal interference introduced by wellbore geometry, rate variations, fracturing fluid composition, and low sampling frequency. read more…

Visualizing the Big (data) Picture

For many operators, it seems like the well is a baton handed off from the drilling team to the completions team to the production team. Each group has their own tools, their own questions, and their own ideas about what makes for a quality well. But at the end of the day, the only thing that really matters is the performance of the well itself – is it producing or not?

I’ve been reading more and more articles with the same thesis: as the amount of data collected on unconventional plays increases, it can be used to build advanced analytics that drive towards successful wells. But this data only really begins to be meaningful when it is interconnected with other big data sets. True data integration across teams has an immense potential for answering challenging questions about the relationship between the decisions made at each stage of a well’s life and its performance.

What Computers Can do for Your Oil & Gas Data that Humans Cannot

Guest Post by Ky Kiefer

We often design hydraulic fracturing treatments around historical success. We look to the successes (and failures) of “wildcatters” of the past and attempt to replicate treatment designs. Once we have a baseline treatment that tends to perform within a formation, we strive for continuous improvement by adjusting our baseline treatment in controlled ways and, all the while, evaluating the efficacy of each adjustment. These kinds of experiments are conducted by scientists, engineers, and statisticians in the lab and field with tools such as Excel, SpotFire, proprietary simulation software, and various programming languages. However, the full power of data is just beginning to be leveraged industry-wide for two reasons:

Diverter Effectiveness – Analyzing One Piece of the Puzzle

In today’s industry climate, operators are relying on large data sets more than ever to make intelligent design decisions when it comes to drilling and completing wells. The first step in making those decisions is establishing a detailed understanding of what happened in previously drilled wells. But, as any engineer who has attempted such an endeavor clearly knows, this is more easily said than done. Many of the data sets vital to understanding the full story of what happened on an old well are challenging to analyze, much less compare against each other. At Well Data Labs, we work to make one of these data sets, detailed frac data, structured and useful for engineers so that they can answer questions and gain the insight needed to do what they do best: design more efficient wells. To better understand what happens when engineers are armed with the right data, we sat down with Darren Kirkwood to discuss the analysis he was able to carry out on completions data using the Well Data Labs application during his time at Fuse Energy.

The Refrac: Pumping New Life Into Shale

For as long as hydraulic fracturing, or fracing, has existed, the story goes the same way.

A well is drilled, cased, completed, and put on production. And the story always ends the same way too – eventually the well runs dry. Companies move on to tap new wells because the play is played out.

Right? Well, maybe not. Since the start of the downturn two years ago, more and more companies are evaluating the idea of trying to pump some new life into old wells.

Enter refracing (or hydraulic refracturing), and enter the industry’s latest attempt to stay alive in a low price environment. read more…

Pretty Treating Plots Don’t (Necessarily) Mean Pretty Production

I’m not an engineer. I was headed that way during my first year of undergrad at Virginia Tech’s College of Engineering, but I eventually yielded to the tempting promises of entrepreneurship proffered by the business school. Now, a decade later, I find myself leading business development for a tech company, but spending a significant portion of my time attending professional engineering lectures and trying to dissect and interpret fluid mechanics. I should have stayed in school… read more…

Bridging the IT Divide – Part 2

This is a series of guest posts by author and industry-insider Jim Crompton. Crompton is an Energy Advisor for Rocky Mountain Innosphere and an independent consultant through Reflections Data Consulting LLC.

Getting to know IT

I hope that I am catching you before you have formed too critical of an opinion of your IT department. I know that the coffee pot conversations can sometime get pretty tough on IT. I can still remember when I was first transferred into the IT department (with a considerable promotion), and all I got from my former peers from earth science was skepticism, condolences and criticism. “What did you do wrong to get that job?,” they asked me. But IT is not that bad and the work they do is critical to the running of your company. So let’s talk about why they are not always on your side.

Big Data or Buzzword Bingo?

Published over a month ago, I just had the opportunity to read a fantastic article by Anya Litvak of the Pittsburgh Post-Gazette, and thought it was worth sharing. Titled “Shale companies turn to machines to crunch their drilling data,” Anya does a wonderful job of succinctly breaking down both the opportunities and the challenges of working with high-frequency, machine created data in the world of unconventionals. Included in the article are highlights of the work of WVU’s Shahab Mohaghegh, a major SPE contributor and industry data scientist, and the efforts of major E&P’s and service companies like Shell, Range Resources, Southwestern, and Baker Hughes.

What do you think – is ‘Big Data’ an overused buzzword in our industry, or the beginnings of a smarter E&P “corporate brain,” as Neal Dikeman of Shell describes it?